What Is Laser Cutting?

Laser cutting and engraving are methods that use a strong laser beam to cut or mark designs into various materials without touching them. These techniques are popular in many fields, including manufacturing, fashion, jewelry, and advertising, because they are precise and can work with many materials. Laser cutting is great for making detailed shapes and fine designs in metals, plastics, glass, wood, and fabric. Laser engraving is used to create detailed pictures and text with clear and deep marks on similar materials.

The technology for laser cutting and engraving has improved a lot, making these methods more capable and efficient. Modern lasers have very focused beams that can cut or engrave with high precision and create smooth edges, which reduces the need to fix or clean up the pieces afterward. New types of lasers, like fiber lasers, use less energy and can cut through thicker and harder materials quickly. Also, by using CNC (Computer Numerical Control) technology, the laser processes can be automated, which means they can consistently produce large amounts of products accurately. These systems can easily switch between cutting and engraving, which saves time and allows for more versatile designs.

Advanced software and control systems are crucial for getting the best results from laser cutting and engraving. CAD/CAM software helps design complex patterns and then turns these designs into digital instructions that control how the laser moves, its power, speed, and focus. This software handles intricate designs that need to be very precise. Also, modern laser systems can adjust themselves in real-time during the cutting or engraving process, which helps fix any issues automatically. This keeps the quality consistent and reduces wasted materials. Using these advanced technologies, laser cutting and engraving have become essential tools for making precise and detailed items in various industries.

What we recommend?

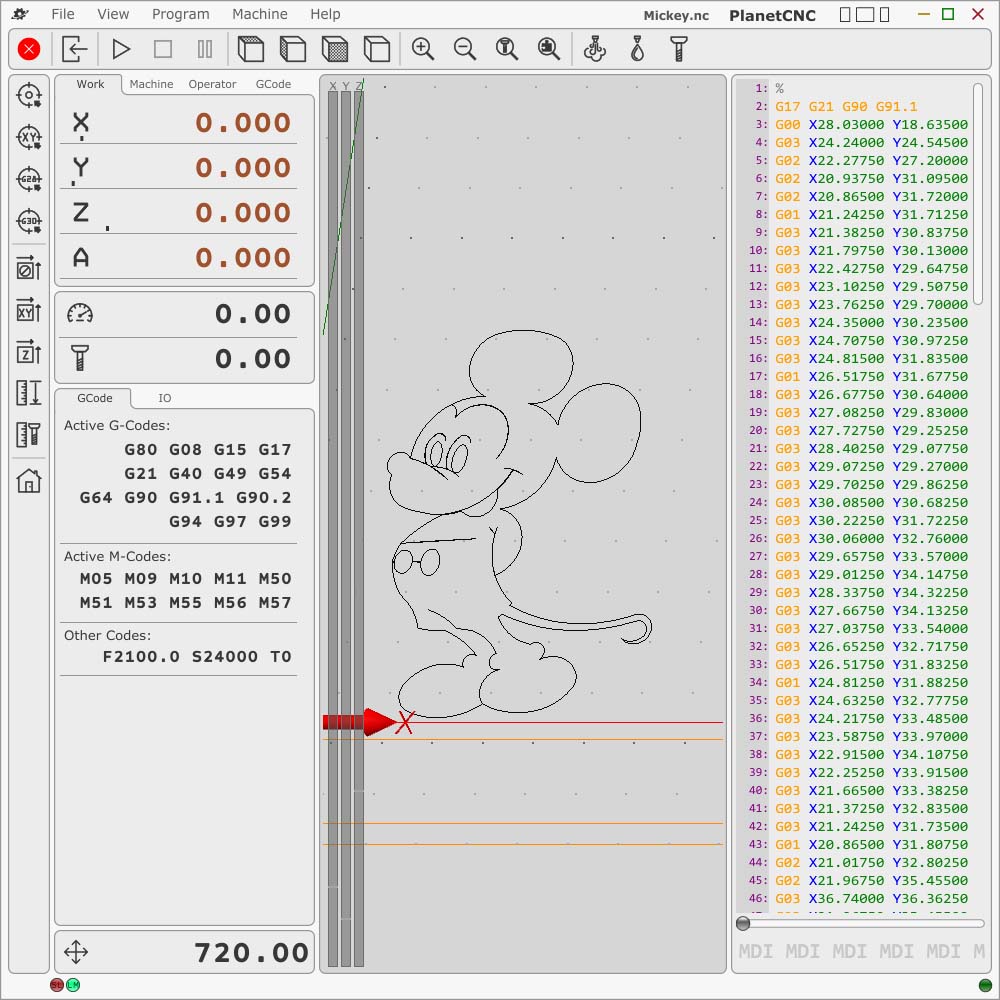

Choose PlanetCNC TNG software to get:

Comprehensive Compatibility: PlanetCNC TNG software works well with many CNC milling machines. This makes it easy to use the software with different types of equipment, ensuring you can handle many kinds of milling projects, from small prototypes to large productions.

Advanced Features and User-Friendly Interface: The software has many advanced options like full cutter compensation, advanced algorithms for shaping, and supports both 3D and traditional 2D milling. It is designed to be user-friendly, helping users do their work more efficiently and making complex tasks simpler.

Robust Support for G-Code and CAM Programs: PlanetCNC TNG software is compatible with G-code from leading CAM (Computer-Aided Manufacturing) programs. This means you can easily bring in and use designs from various CAD/CAM software, making your work process smoother and decreasing the chance of mistakes when moving from design to actual milling.

Choosing between the PlanetCNC Mk3/9 and Mk3/4 controllers depends on several factors including your specific needs, budget, and the complexity of your CNC operations. Here are some recommendations to consider:

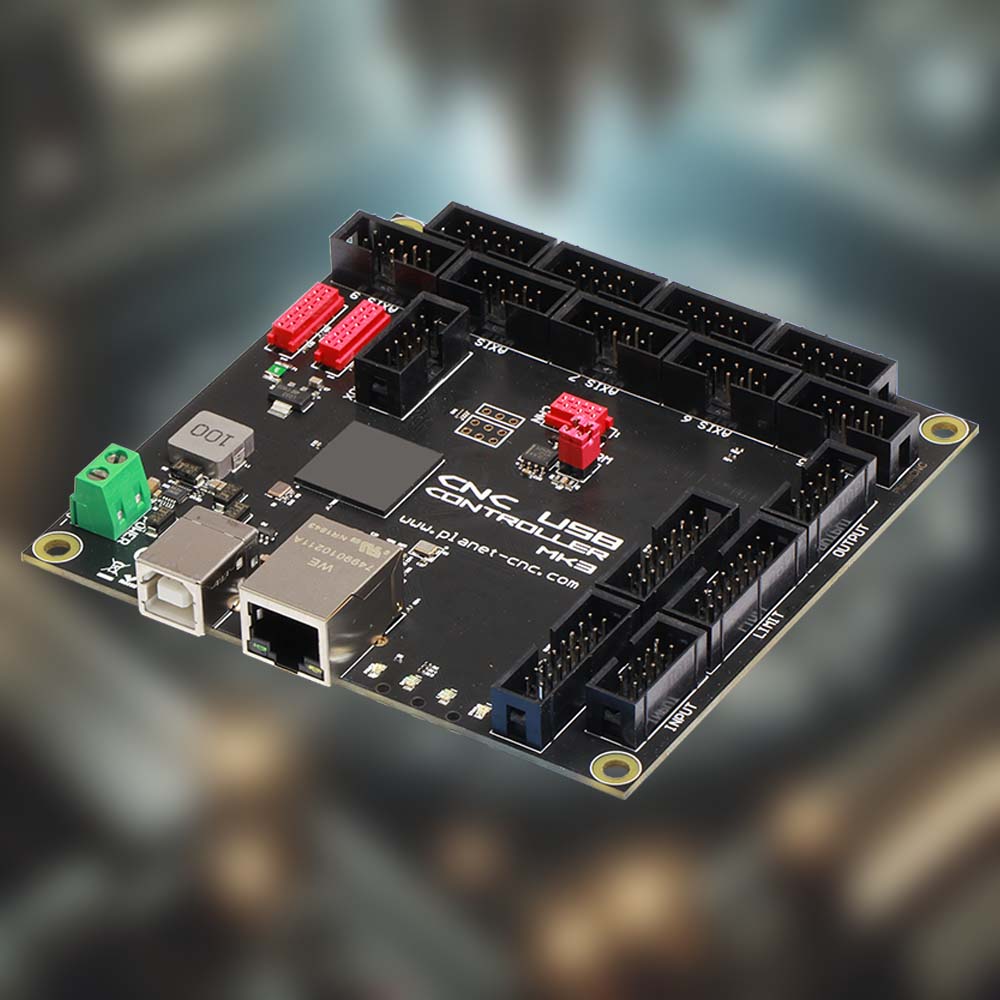

Choose the Mk3/9 Controller if:

You Require More Inputs and Outputs: If your CNC operations involve complex setups or you anticipate needing to manage multiple tools and processes simultaneously, the Mk3/9 controller's increased number of inputs and outputs can be extremely beneficial. This would be especially useful in production environments where automation and precision are critical.

You Need Ethernet Connectivity: The Mk3/9’s Ethernet capability enhances robustness to connect seamlessly with other components for stable integration into modern workshop environments. This is particularly valuable for noisier environments that have lot of equipment that produces electrical interference.

Future Expansion: If you plan to scale up your operations or think you might need to upgrade your system capabilities in the future, investing in the Mk3/9 could save you from needing to buy a new controller later on.

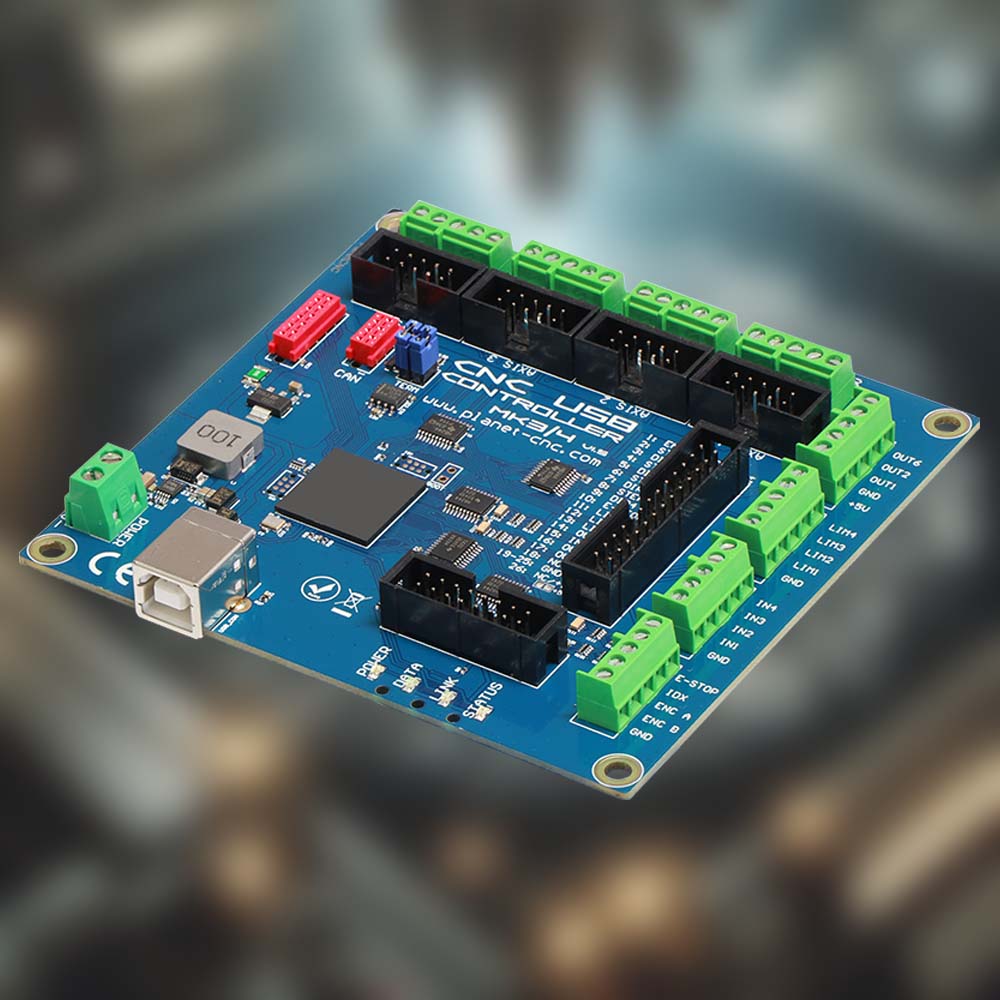

Opt for the Mk3/4 Controller if:

You Are on a Tight Budget: If cost is a significant constraint, the Mk3/4 offers a more budget-friendly option that still delivers the core functionalities needed for efficient CNC milling.

Your Operations Are Less Complex: For smaller operations or if you're just starting out and don't require a large number of inputs and outputs, the Mk3/4 controller should suffice. It provides the essential features needed for effective CNC control without the additional cost for capabilities that you may not use.

Simplicity is Key: If your project or workshop benefits from a straightforward setup without the need for advanced networking, the simpler Mk3/4 can meet your needs effectively.

In summary, if your operations and future plans justify the need for more connectivity and versatility, and the budget allows, the Mk3/9 is likely the better choice. However, if you are looking to save money and your current requirements are modest, the Mk3/4 will serve you well.