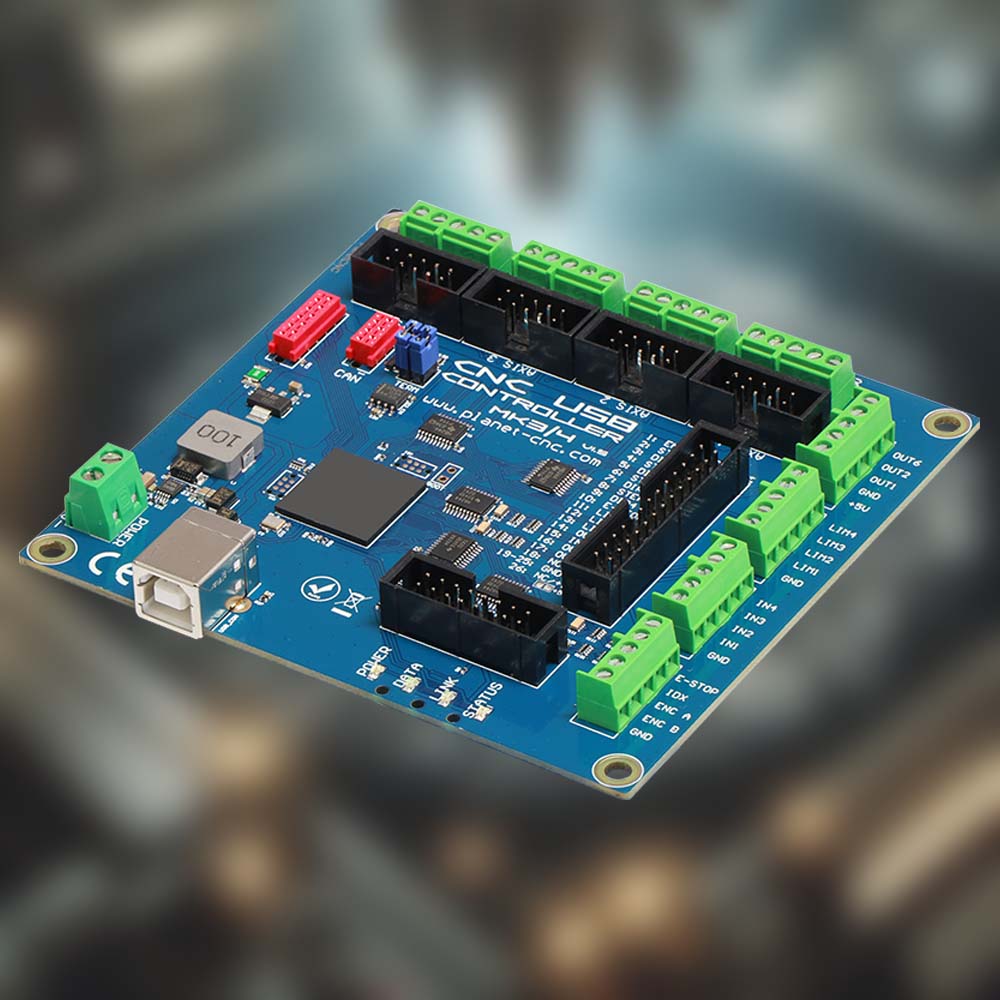

PlanetCNC Mk3/9 CNC Controller

The PlanetCNC Mk3/9 CNC controller is a versatile device designed to control various machines, such as routers, mills, and lathes. It is well-suited for controlling both stepper and servo motors, making it a flexible option for different types of machinery. This controller is packed with features that make it powerful yet user-friendly, ideal for both beginners and experienced users in the CNC field.

Key Features of the PlanetCNC Mk3/9 CNC Controller

1. Multiple Axis Control:

2. Diverse Output Options:

3. Comprehensive Input Capabilities:

4. Connectivity and Interface Options:

Conclusion

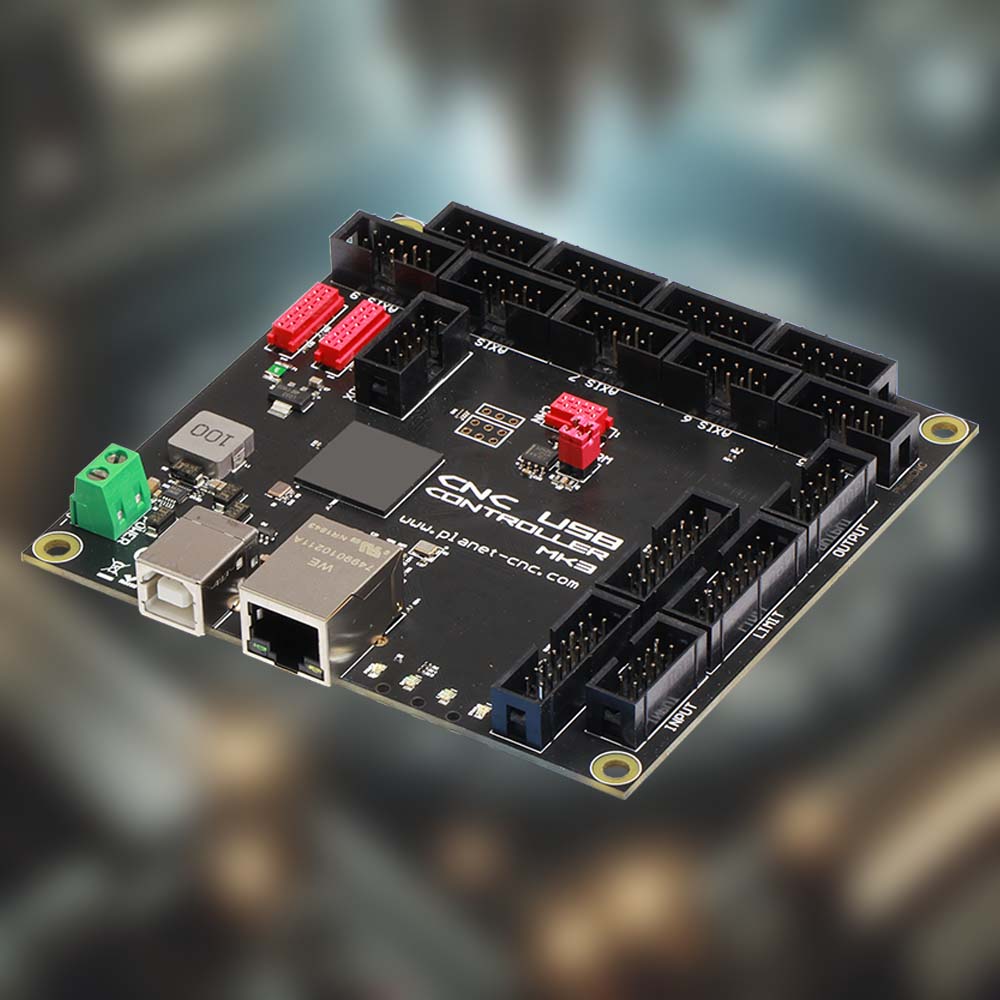

PlanetCNC Mk3/4 CNC Controller

The PlanetCNC Mk3/4 CNC controller is a specialized device designed to control CNC machines such as routers, mills, and lathes. These machines are used to cut and shape various materials with precision. The Mk3/4 controller is compatible with both stepper motors, which move in exact increments, and servo motors, known for their accuracy and speed. This controller is equipped with features that make it easy to use and efficient, ideal for both beginners and experienced operators.

Key Features of the PlanetCNC Mk3/4 CNC Controller

1. Multiple Axis Control:

2. Output Features:

3. Input Features:

4. Connectivity and Additional Controls:

Conclusion

CNC Controller Accessories

CNC controllers are devices used to operate machines like routers, lathes, and mills. These machines cut and shape materials with precision. To make CNC controllers more effective and versatile, various accessories are available. These accessories help improve the performance and functionality of CNC machines. Each accessory comes with a cable included, making it easy to connect and set up.

Key Accessories for CNC Controllers

1. Optically Isolated Limit Switches:

2. Optically Isolated Inputs:

3. Optically Isolated Spindle Encoder Input:

4. Output Board with Relays and 0-10V for Spindle Speed:

5. Wireless Handwheel:

6. Jogging Keyboard:

Conclusion