What Is Foam Cutting?

Hot wire foam cutting is a method used to cut foam materials such as polystyrene and polyurethane using a heated wire. The heat from the wire melts the foam just before it cuts, allowing for clean and accurate cuts without any physical force. This technique is popular in fields like construction, model making, and theater set design because it can easily shape lightweight foam into complex shapes and sizes.

Recently, hot wire foam cutting has become more precise and versatile. Today's hot wire cutters often use CNC (Computer Numerical Control) technology, which allows for very precise cuts that repeat exactly and are based on digital designs. This makes it possible to create detailed and complicated designs that would be hard to make by hand. The cutters can be adjusted to change the heat based on the type of foam and its thickness, improving the cut quality and making the process better. Some machines can use multiple wires or different shapes of wires at the same time, increasing how much they can produce and the variety of cuts they can make.

The success of hot wire foam cutting depends a lot on the software and control systems used. These systems precisely manage the temperature and movement of the wire, which is important for making accurate cuts and keeping the quality consistent across different pieces. CAD (Computer-Aided Design) software is used to design the shapes, which are then converted into G-code that tells the machine how to move. This setup minimizes human mistakes and ensures each piece is cut exactly to the planned specifications. Moreover, advanced machines might have features like automatic wire tension adjustment and real-time monitoring to adjust to changes in the foam's resistance, improving the cutting precision. With these technological advances, hot wire foam cutting has become a dependable and efficient way to produce detailed and accurately sized foam pieces.

What we recommend?

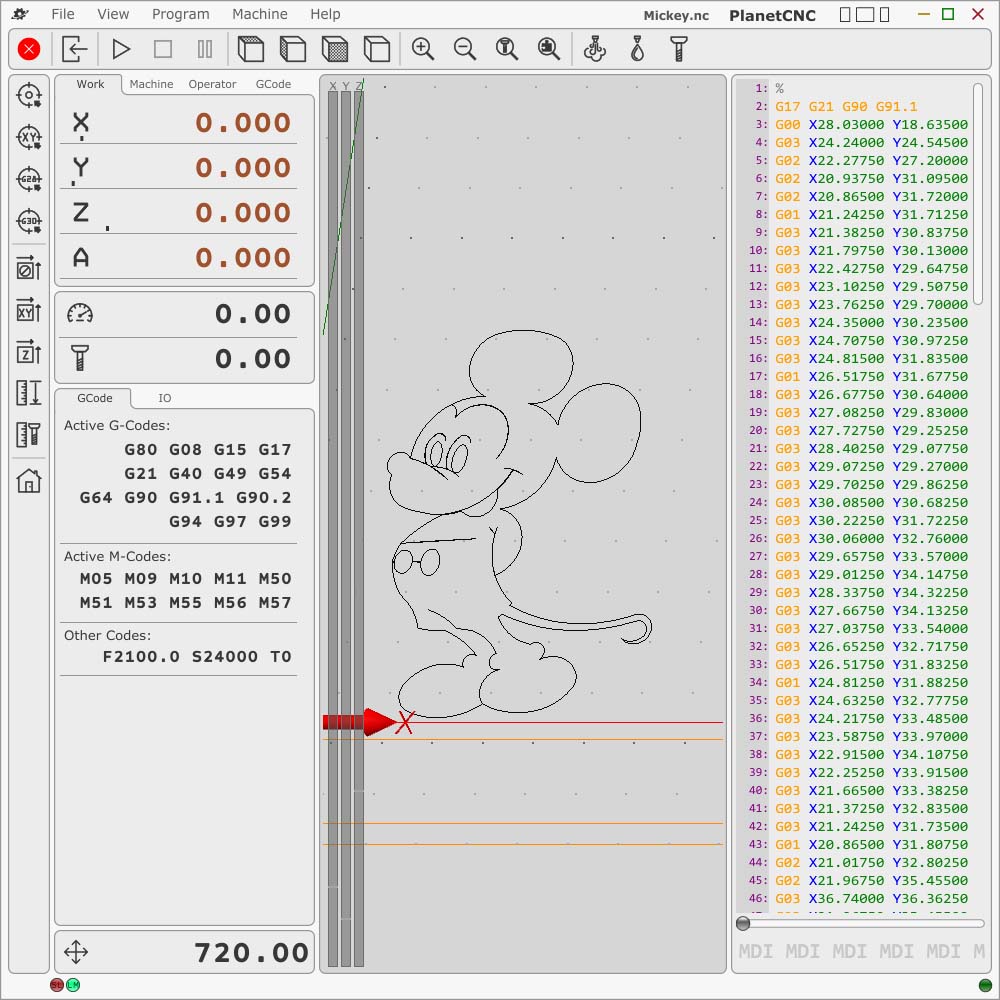

Choose PlanetCNC TNG software to get:

Comprehensive Compatibility: PlanetCNC TNG software works well with many CNC milling machines. This makes it easy to use the software with different types of equipment, ensuring you can handle many kinds of milling projects, from small prototypes to large productions.

Advanced Features and User-Friendly Interface: The software has many advanced options like full cutter compensation, advanced algorithms for shaping, and supports both 3D and traditional 2D milling. It is designed to be user-friendly, helping users do their work more efficiently and making complex tasks simpler.

Robust Support for G-Code and CAM Programs: PlanetCNC TNG software is compatible with G-code from leading CAM (Computer-Aided Manufacturing) programs. This means you can easily bring in and use designs from various CAD/CAM software, making your work process smoother and decreasing the chance of mistakes when moving from design to actual milling.

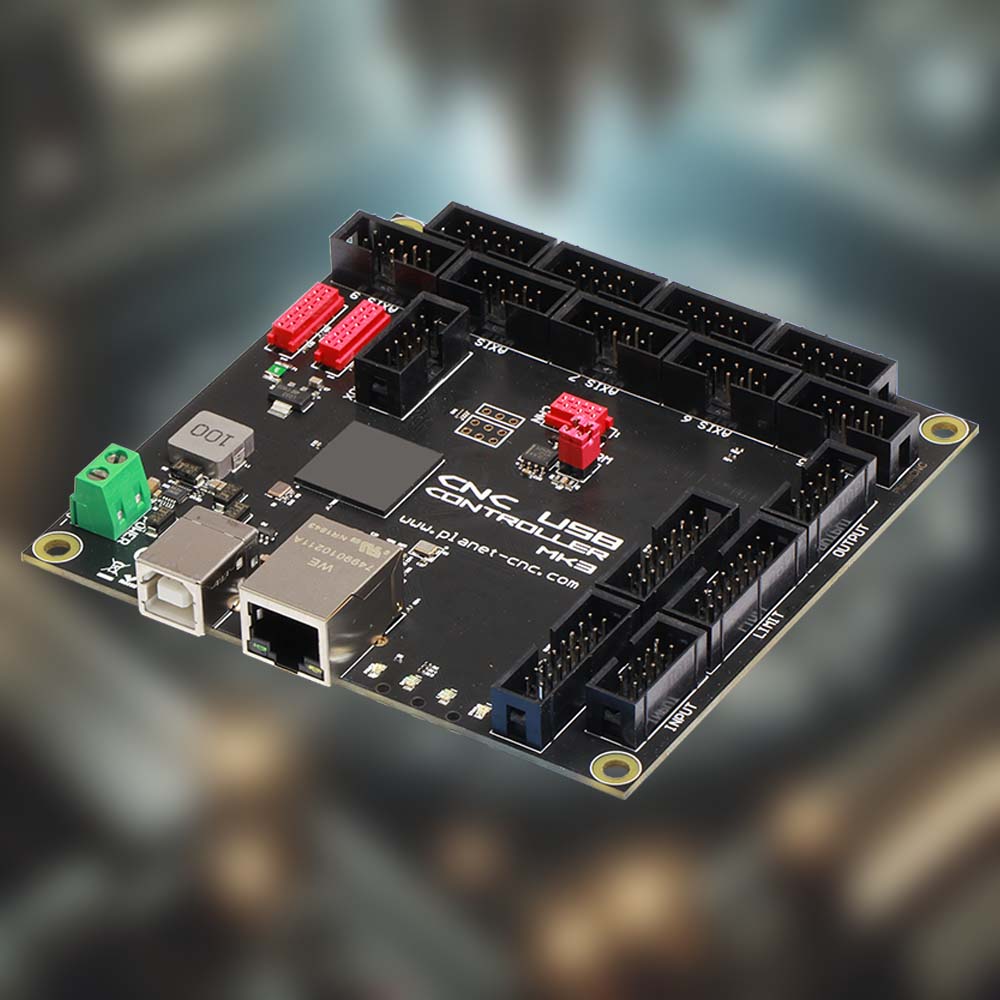

Choosing between the PlanetCNC Mk3/9 and Mk3/4 controllers depends on several factors including your specific needs, budget, and the complexity of your CNC operations. Here are some recommendations to consider:

Choose the Mk3/9 Controller if:

You Require More Inputs and Outputs: If your CNC operations involve complex setups or you anticipate needing to manage multiple tools and processes simultaneously, the Mk3/9 controller's increased number of inputs and outputs can be extremely beneficial. This would be especially useful in production environments where automation and precision are critical.

You Need Ethernet Connectivity: The Mk3/9’s Ethernet capability enhances robustness to connect seamlessly with other components for stable integration into modern workshop environments. This is particularly valuable for noisier environments that have lot of equipment that produces electrical interference.

Future Expansion: If you plan to scale up your operations or think you might need to upgrade your system capabilities in the future, investing in the Mk3/9 could save you from needing to buy a new controller later on.

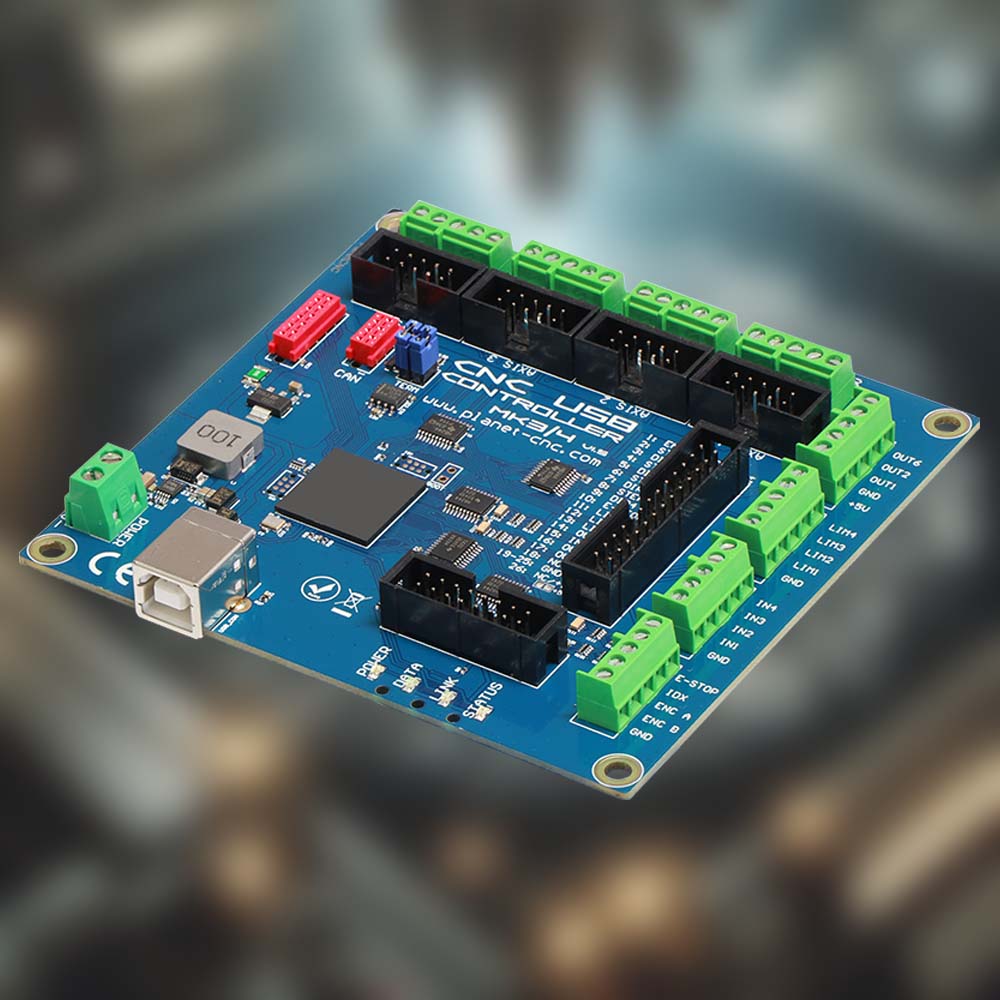

Opt for the Mk3/4 Controller if:

You Are on a Tight Budget: If cost is a significant constraint, the Mk3/4 offers a more budget-friendly option that still delivers the core functionalities needed for efficient CNC milling.

Your Operations Are Less Complex: For smaller operations or if you're just starting out and don't require a large number of inputs and outputs, the Mk3/4 controller should suffice. It provides the essential features needed for effective CNC control without the additional cost for capabilities that you may not use.

Simplicity is Key: If your project or workshop benefits from a straightforward setup without the need for advanced networking, the simpler Mk3/4 can meet your needs effectively.

In summary, if your operations and future plans justify the need for more connectivity and versatility, and the budget allows, the Mk3/9 is likely the better choice. However, if you are looking to save money and your current requirements are modest, the Mk3/4 will serve you well.