How to use moveable sensor?

– Offset – Current XY gives us relative coordinates. We can set Offset XY position

coordinates anywhere on the machines table. This way we can adjust our imported

program (G-code) to our table size and therefore set position that is most suitable

for machining our work piece.- Offset – Current Z gives us relative coordinates. We can set Offset Z Zero position of our work piece.

This is usually top surface of work material.Before we continue:Offset- Measure Offset Z feature is used for measuring Offset Current Z with movable tool sensor.

Difference between Offset-Current Z ![]() and Offset -Measure Offset Z

and Offset -Measure Offset Z ![]() feature:

feature:

– When we use Offset-Current Z feature, we must jog Z axis by hand until we set current

Z offset value (top surface).

-When we use Offset-Measure Offset Z, software automatically sets current Z Offset,

by detecting the surface of movable sensor with machines tool. Height of movable sensor is

already compensated since we have set parameters of sensor in Tool Sensor Settings.

OFFSET – MEASURE OFFSET Z FEATURE

This tutorial will explain how to correctly use Offset – Measure Offset Z feature with movable

sensor using PlanetCNC software and controllers.

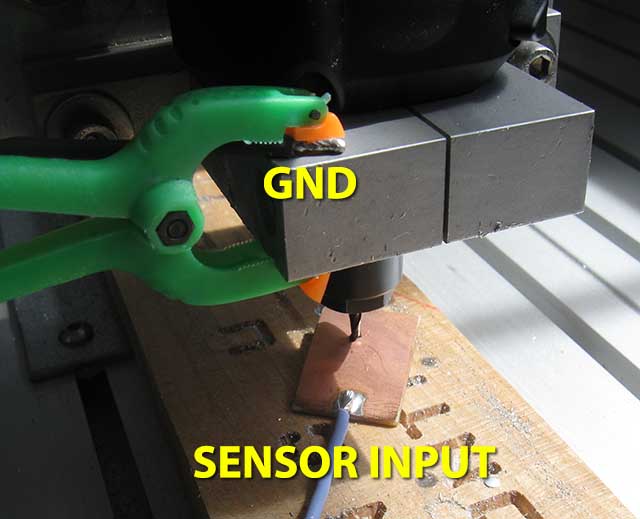

Movable Sensor

Movable sensor is basically a switch that sends signal to controllers input pin.

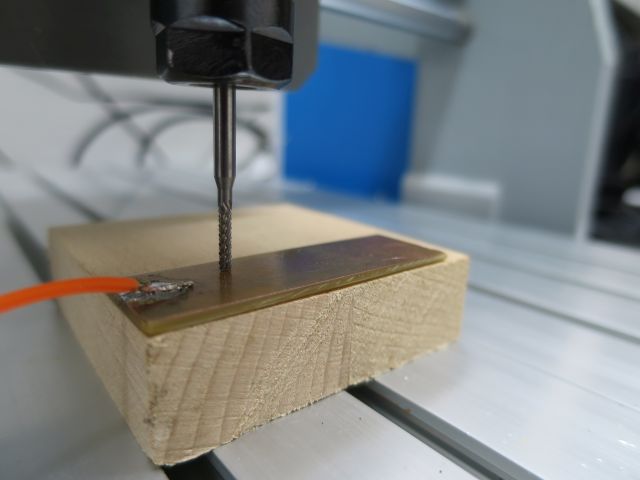

When tool touches sensors surface (it’s the same as normal switch would be activated),

controllers input goes ‘Low’ and therefore software is able to set Current Offset Z.

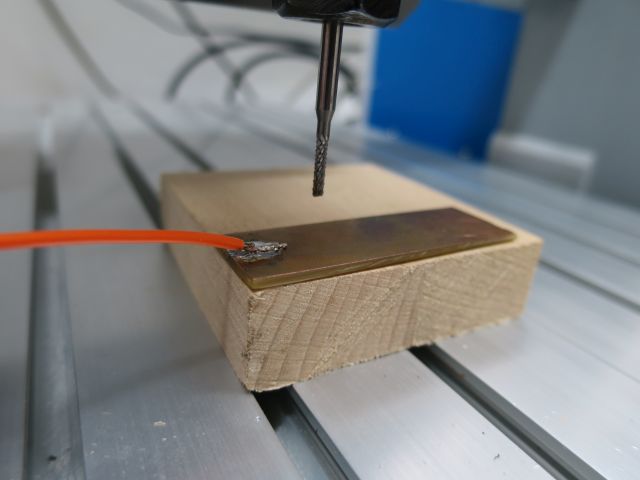

The most basic type of movable sensor is usually copper-clad laminate, that has wire soldered onto it,

which is connected to controller sensor input. GND signal is attached to tool via crocodile clip.

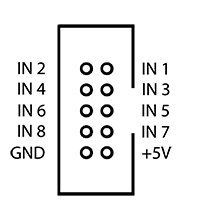

Connecting Movable Tool Sensor to PlanetCNC controllers

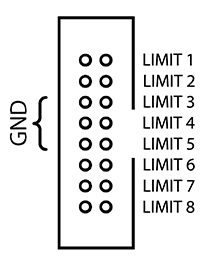

Mk1:

Tool Sensor is connected to LIMIT 5 (Z-) input pin of MK1 LIMIT Connector.

Mk1 LIMIT connector

Mk1 LIMIT connector

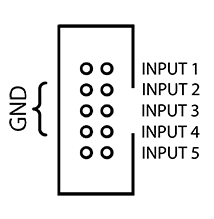

Mk2/4 and Mk2:

Tool Sensor is connected to INPUT 5 (Tool Sensor) pin of Mk2/4 and Mk2 INPUT connector.

Mk2 INPUT connector

Mk2 INPUT connector

Mk2/4 INPUT connector

Mk2/4 INPUT connector

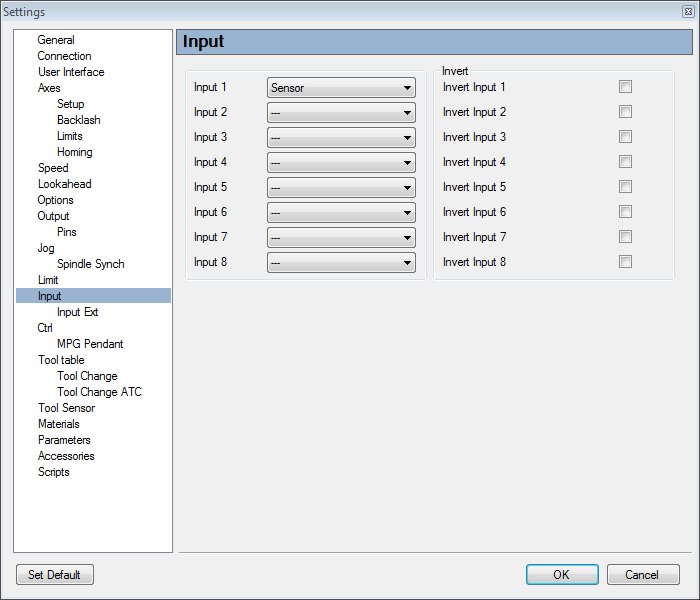

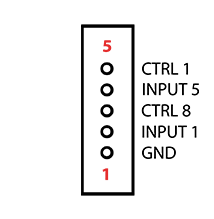

Mk3:

Mk3 provides inputs for user-assigned functions. Tool sensor can be connected to any input pin of

INPUT connector, and assigned in software as Sensor.

Mk2 INPUT connector

Mk2 INPUT connector

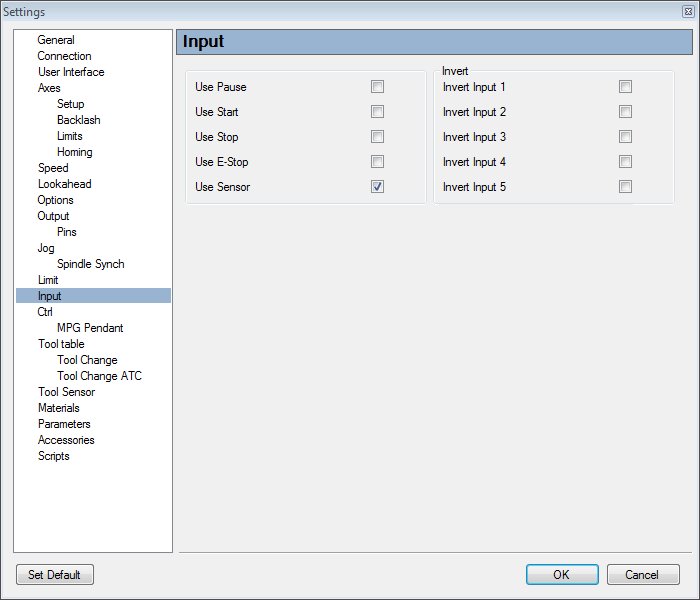

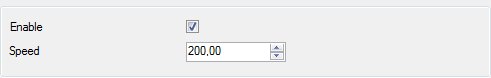

Software Settings for Movable Tool Sensor

Tool sensor option in File/Settings/Tool Sensor must be enabled for tool measuring procedures.

You can also set Speed, at which tool will descend when doing measurement.

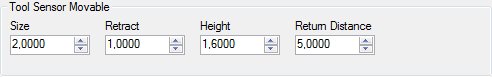

We must set Sensors parameters:

Size: If we use sensor or touching probe to measure X and Y coordinates then this value

represent radius of stylus ball at the point of touching probe. This is the same as

Height parameter for measuring Z coordinates.

Retract: Value represents distance for which tool retracts once it has touched the surface of sensor.

Height: Thickness of material that is used for sensor.

Return Distance: Value represents distance for which machine ascends (from height to which previously retracted to).

Setting Offset – Measure Offset Z

Mk1:

Measurement of current Z offset is semi-automatic procedure for Mk1. We set movable sensor on top surface of our work material. Make sure that tool is above the sensor.

1) Click “Measure Offset Z” button:

![]()

2) When tool touches the sensor, “Measure Offset Z” button will turn orange:

![]()

3) Now click “Offset-Current Z” button

![]()

4) Click again on the orange “Measure Offset Z” button.

This will turn “Measure Offset Z” button back in normal color.

![]()

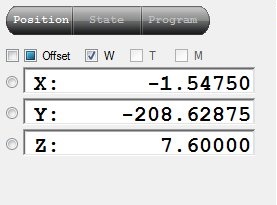

Mk2/4, Mk2, Mk3:

The measurement is atomatic procedure.

We set movable sensor on the top surface of our work material. Make sure that tool is above the sensor.

Now click Measure- Offset Z ![]() button, or set offset through Machine menu: Machine/Offset/Measure offset Z.

button, or set offset through Machine menu: Machine/Offset/Measure offset Z.

Machine will descend until tool touches our sensor. Then it will immediately move up to specified position.

Value of relative Z coordinate when machine finishes with measurement, is sum of sensors parameter values.

Retract + Height + Return Distance = Current Z value

Retract + Height + Return Distance = 1+ 1,6 + 5 = 7,6