Using o-words with PlanetCNC TNG software: Loop blocks

You can use loop o-words with PlanetCNC TNG.

Sometimes you need to execute line(s) of g-code in a loop while evaluating specific condition. When condition evaluates to false, program will exit loop. This comes useful for e.g. repetitive motion sequences, parameter manipulation etc…

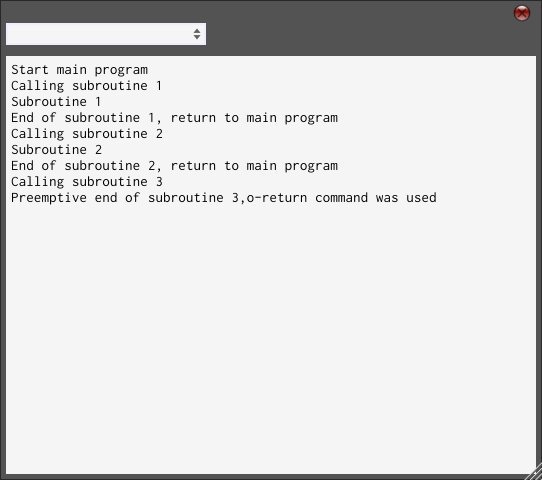

O-word loop commands consist of:

O-do – Begin loop block

O-while – End loop block [or condition evaluation]

O-endwhile – End loop block

O-break – Exit loop block immediately

O-continue – Skip to next condition evaluation of the while condition

You can use two types of loops: While – Endwhile or Do – While.

While – Endwhile:

Evaluates condition on the beginning of loop and then executes the lines of code inside the loop.

Do – While:

First executes the lines of code inside the loop and then evaluates condition at the end of loop.

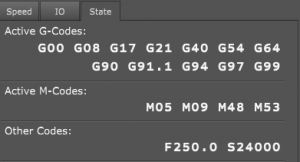

Example of Do – While loop:

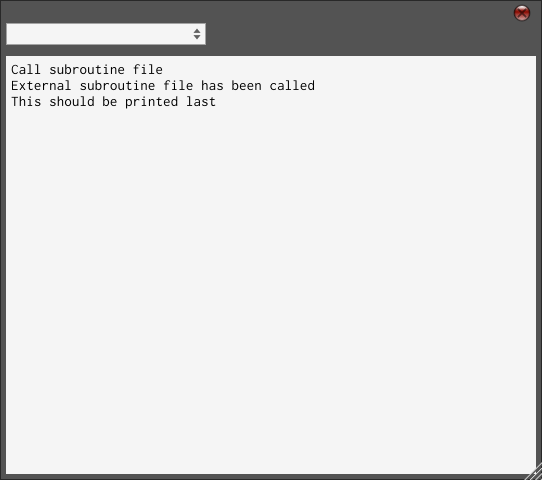

% #1 = 1 o100 do (print, #1) #1 = [#1+1] o100 while[#1 LE 10] (print,loop finished) %

The content of the loop will repeat for as long as while condition at the end will remain true. Which means that as soon as parameter #1 exceeds value of 10, program will exit the loop and print

loop finished

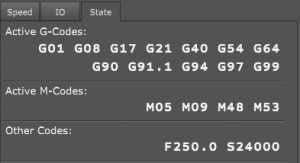

Example of While – Endwhile loop:

% #1 = 1 o100 while [#1 LE 10] (print, #1) #1 = [#1+1] o100 endwhile (print,loop finished) %

The content of the loop will repeat for as long as while condition at the beginning will remain true. Which means that as soon as parameter #1 exceeds value of 10, program will exit the loop and print

loop finished

Example of break used in a Do – While loop:

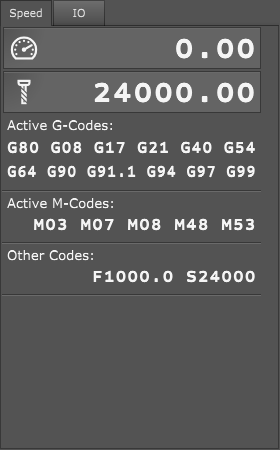

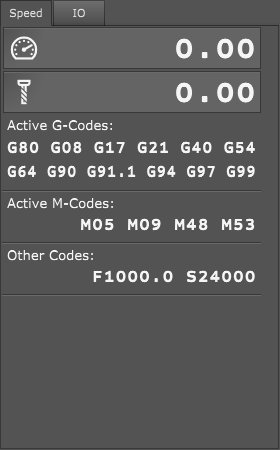

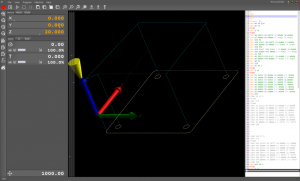

% #<A> = [2**0] #<B> = 0 #1 = 0 o100 do (print, #1) #1 = [#1+1] G04 P1 o200 if [AND[#<A>, #<_hw_input>]] #<B> = 1 o100 break o200 endif o100 while[#1 LE 10] o300 if [#<B> EQ 0] (print,loop finished) o300 else (print,preemptive loop break) o300 endif %

The content of the loop will repeat for as long as input 1 of controller is not active and while condition at the end remains true. Which means that as long as input 1 remains un-active, counter will count to 10 and program will exit the loop normally and print:

loop finished

As soon as input becomes active during counting, program will exit loop and print:

preemptive loop break